Multiple workers were in a man basket being hoisted out of a tunnel shaft. While the man basket was being lifted by crane and swung in the direction of an excavator, the excavator operator began to swing the bucket to remove dirt from a ventilation vault area. In doing so the elevated man basket struck the elbow of the excavator. The workers were not seriously injured, and the ensuing investigation focuses on training and communication. But did anyone ever ask whether the man basket needed to be swung in the same direction as the operating equipment?

Hierarchy of Controls

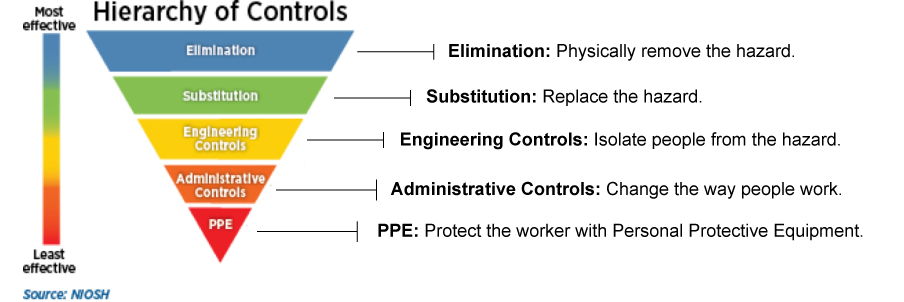

The Hierarchy of Controls method is designed to meet the number one goal for all safety and health professionals – creating the safest possible work environment for everyone. Before work begins all exposures must be identified and mitigated. NIOSH offers a basic outline through its understanding of the Hierarchy of Controls. The hierarchy starts with the controls understood to be most effective and moves down to those believed least effective. As defined by NIOSH, it flows as follows:

You cannot remove every hazard, but the closer you can get to the top, the closer you can get to meeting that number one goal of creating the safest work environment for everyone.

Cooperative thinking should take place prior to developing a pre-task plan for each operation. Bringing together as many experts as possible, including supervisors, engineers, operators, and workers will bring about inherently safer thinking. Get input from workers who may be able to suggest and evaluate solutions based on their knowledge of the facility, equipment, and work processes. There is never a guarantee that every hazard will be eliminated, but the chances are much greater with everyone involved.

Referring to the man basket example, the Elimination Control could have been used to drop the man basket in a different area of the job site rather than swinging it over top of active heavy equipment operations. All hazards must be identified prior, to be able to eliminate associated risks. Changing thought patterns may establish a way to develop less hazardous processes.

NIOSH states that Elimination and Substitution are often more difficult to enact after work has begun. The goal of Substitution is to replace a hazardous product or process with a safer one. Examples include using non-toxic or less toxic chemicals and upgrading aging machinery with newer equipment. If substitution is not an option, Engineering Controls are the next best option. NIOSH identifies numerous hazards for which Engineering Controls can be effective. For example, exhaust ventilation systems can be installed to remove airborne emissions. Another example would be adding machine guarding to protect operators.

Administrative Controls limit exposure to hazards by adjusting work tasks or schedules. This could include limiting time a worker is exposed to a hazard. Other examples include creating written standard operating procedures or installing alarms, signs, and warnings. Some organizations enact a buddy system for employees to look out for one another.

OSHA states that use of PPE should be the last line of defense or control considered. This is only acceptable after all other higher controls were considered and all efforts were exhausted. There are many types of PPE available but the right one must be chosen. After PPE has been identified as the only option, another pre-task hazard assessment must be completed to make the decision on what type is best for the job.

The Take-Away

Take time to thoroughly discuss every work operation with the ultimate outcome of getting rid of all hazards entirely. Build a team of experts who can collaborate and make these efforts a reality. Work your way through the Hierarchy of Controls and do not move onto the next type of control until necessary. Have an open mind, set aside the right amount of time, and be prepared to budget the necessary amount of money needed to ensure the safety of your workers.